Scratch Resistance Elastomer compounders le TPV le TPE converter (ente kapa extrusion)

Scratch Resistance Elastomer compounders le TPV le TPE converter (ente kapa extrusion),

,

Tlhaloso

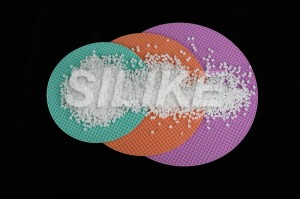

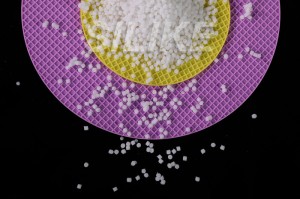

Silicone Masterbatch ( Siloxane Masterbatch ) LYSI-412 ke sebopeho sa pelletized se nang le 50% ultra high molecular weight siloxane polymer e qhalakantsoeng ka liner low density polyethylene (LLDPE).E sebelisoa haholo e le tlatsetso e sebetsang hantle ho sistimi ea resin e lumellanang ea PE ho ntlafatsa thepa ea ts'ebetso le ho fetola boleng ba bokaholimo.

Bapisa le li-additives tse tloaelehileng tse tlase tsa boima ba limolek'hule tsa Silicone / Siloxane, joalo ka oli ea Silicone, maro a silicone kapa lisebelisoa tse ling tsa ho lokisa, SILIKE Silicone Masterbatch LYSI letoto le lebelletsoe ho fana ka melemo e ntlafalitsoeng, mohlala.Ho thella ho fokolang , ho ntlafatswa ha hlobo, ho fokotsa lerotho, ho fokotswa ha khohlano, pente e fokolang le mathata a ho hatisa, le bokgoni bo bongata ba tshebetso.

Mekhahlelo ea Motheo

| Kereiti | LYSI-412 |

| Ponahalo | Pellet e tšoeu |

| Likahare tsa silicone % | 50 |

| Motheo oa resin | LLDPE |

| Qhibiliha index (230℃, 2.16KG) g/10min | 4.0( boleng bo tloaelehileng) |

| Dosage% (w/w) | 0.5~5 |

Melemo

(1) Ntlafatsa thepa ea ts'ebetso e kenyelletsang bokhoni bo betere ba phallo, phokotso ea "extrusion die drool", torque e nyane ea extruder, ho tlatsa ho bōptjoa hantle le ho lokolloa.

(2) Ntlafatsa boleng ba bokaholimo joalo ka slip ea holimo, Coefficient e tlase ea khohlano.

(3) E kholoanyane abrasion & mongoapo ho hanyetsa

(4) Phallo e potlakileng, fokotsa sekhahla sa sekoli sa sehlahisoa.

(5) Ntlafatsa botsitso ha o bapisoa le lithuso tsa khale tsa ho lokisa kapa mafura

….

Lisebelisoa :

(1) lik'hemik'hale tsa cable tsa HFFR / LSZH

(2) Lisebelisoa tsa cable tsa XLPE

(3) Pipe ea puisano ea mohala , HDPE microduct

(4) Likhoele tsa maiketsetso

(5) filimi ea polasetiki ea PE

(6) metsoako ea TPE / TPV

Li-plastiki tse ling tse lumellanang le PE

Mokhoa oa ho sebelisa

SILIKE LYSI letoto la silicone masterbatch le ka sebetsoa ka mokhoa o ts'oanang le sejari sa resin seo ba se thehileng ho sona.E ka sebelisoa ts'ebetsong ea khale ea ho qhibiliha joalo ka Single / Twin screw extruder, molding ea ente.Ho khothaletsoa ho kopanya 'mele le li-pellets tsa polymer tse sa tsoakoang.

Khothalletsa litekanyetso

Ha e kenngoa ho polyethylene kapa thermoplastic e tšoanang ho 0,2 ho 1%, ho lebeletsoe ho ntlafatsa ts'ebetso le ho phalla ha resin, ho kenyelletsa le ho tlatsa hlobo e ntle, torque e fokolang ea extruder, lubricant ka hare, ho lokolloa ha hlobo le ho phalla ka potlako;Boemong bo phahameng ba tlatsetso, 2 ~ 5%, ho lebelletsoe thepa e ntlafalitsoeng ea bokaholimo, ho kenyelletsa le lubricity, ho thella, coefficient e tlase ea likhohlano le khanyetso e kholo ea mar/scratch le abrasion.

Sephutheloana

25Kg / mokotla, mokotla oa pampiri oa matsoho

Polokelo

Lipalangoang joalo ka lik'hemik'hale tse seng kotsi.Boloka sebakeng se phodileng, se nang le moya o hlwekileng .

Shelf bophelo

Litšobotsi tsa mantlha li lula li sa fetohe bakeng sa likhoeli tse 24 ho tloha ka letsatsi la tlhahiso, haeba li bolokiloe sebakeng se khothaletsoang.

Shelf bophelo

Chengdu Silike Technology Co., Ltd ke moetsi le mofani oa thepa ea silicone, ea inehetseng ho R&D ea motsoako oa Silicone le thermoplastics bakeng sa 20.+lilemo, lihlahisoa tse kenyellelitsoeng empa li sa felle feela ho Silicone masterbatch, phofo ea Silicone, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax le Silicone-Thermoplastic Vulcanizate(Si-TPV), bakeng sa lintlha tse ling. le lintlha tsa tlhahlobo, ka kopo ikutloe u lokolohile ho ikopanya le Mme.Amy Wang Email:amy.wang@silike.cnLi-additives tsa Silicone Masterbatch li kopanya UHMW PDMS hore e be matrix a polypropylene polymer bakeng sa moqolo o phahameng le ho hanyetsa mar.Melemo e eketsehileng e kenyelletsa ponahalo e ntlafetseng ea holim'a metsi, ho ama ha bonolo, ho lokolloa ha hlobo, CoF e tlaase, SQUEAK ELIMINATION, LE TACKINESS REDUCTION.haholo-holo etsa li-compounder tsa Scratch Resistance Elastomer le li-converter tsa TPV le TPE (ente kapa extrusion)

LITLHAKISO TSA SILICONE LE disampole tsa Si-TPV MAHALA HO FETA 100

Mofuta oa mohlala

$0

- 50+

limaraka tsa Silicone Masterbatch

- 10+

limaraka Powder ea Silicone

- 10+

limaraka Anti-scratch Masterbatch

- 10+

limaraka Anti-abrasion Masterbatch

- 10+

limaraka tsa Si-TPV

- 8+

limaraka tsa Silicone Wax

-

Mohala

-

E-mail

-

WeChat

-

Holimo

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur