Selelekela ho Polyolefin le Extrusion ea Filimi

Li-polyolefin, sehlopha sa thepa ea macromolecular e entsoeng ka li-monomer tsa olefin tse kang ethylene le propylene, ke polasetiki e hlahisoang le ho sebelisoa haholo lefatšeng ka bophara. Ho ata ha tsona ho bakoa ke motsoako o ikhethang oa thepa, ho kenyeletsoa litšenyehelo tse tlase, ho sebetsa hantle haholo, botsitso bo ikhethang ba lik'hemik'hale, le litšobotsi tsa 'mele tse ka fetoloang. Har'a lits'ebeliso tse fapaneng tsa li-polyolefin, lihlahisoa tsa lifilimi li na le boemo bo phahameng, li sebeletsa mesebetsi ea bohlokoa ho paketeng ea lijo, likoahelo tsa temo, liphutheloana tsa indasteri, lihlahisoa tsa bongaka le tsa bohloeki, le thepa ea letsatsi le letsatsi ea bareki. Li-resin tse tloaelehileng tsa polyolefin tse sebelisoang bakeng sa tlhahiso ea lifilimi li kenyelletsa polyethylene (PE) - e kenyeletsang Linear Low-Density Polyethylene (LLDPE), Low-Density Polyethylene (LDPE), le High-Density Polyethylene (HDPE) - le polypropylene (PP).

Tlhahiso ea lifilimi tsa polyolefin e itšetlehile haholo-holo ka theknoloji ea extrusion, 'me Blown Film Extrusion le Cast Film Extrusion ke lits'ebetso tse peli tsa mantlha.

1. Ts'ebetso ea ho Ntša Filimi e Blown

Ho ntša filimi e phatlohileng ke e 'ngoe ea mekhoa e atileng haholo ea ho hlahisa lifilimi tsa polyolefin. Molao-motheo oa motheo o kenyelletsa ho ntša polymer e qhibilihisitsoeng ka holimo ka die ea annular, ho etsa parison e nang le marako a masesaane a tšubuhlellano. Ka mor'a moo, moea o hatelletsoeng o kenngoa ka hare ho parison ena, e leng se etsang hore e ruruhe ka har'a bubble e nang le bophara bo boholo ho feta ba die. Ha bubble e ntse e nyoloha, e pholisoa ka matla 'me e tiea ke lesale la moea le ka ntle. Bubble e pholisitsoeng e ntan'o putlamisoa ke sete ea li-nip rollers (hangata ka foreimi e putlamang kapa foreimi ea A) ebe e huloa ke li-traction rollers pele e koalloa holim'a roll. Ts'ebetso ea filimi e phatlohileng hangata e hlahisa lifilimi tse nang le tataiso ea biaxial, ho bolelang hore li bontša tekano e ntle ea thepa ea mechini ka bobeli tataisong ea mochini (MD) le tataisong e ka mose (TD), joalo ka matla a ho tsitlella, ho hanyetsa ho taboha, le matla a tšusumetso. Botenya ba filimi le thepa ea mechini li ka laoloa ka ho fetola karolelano ea ho phatloha (BUR - karolelano ea bophara ba bubble ho bophara ba ho shoa) le karolelano ea ho hula (DDR - karolelano ea lebelo la ho nka ho ea lebelong la ho ntša).

2. Ts'ebetso ea ho Ntša Filimi ea Baetsi

Ho ntsha filimi e lahlehileng ke mokhoa o mong oa bohlokoa oa tlhahiso bakeng sa lifilimi tsa polyolefin, o loketseng haholo-holo bakeng sa ho etsa lifilimi tse hlokang thepa e phahameng ea optical (mohlala, ho hlaka ho hoholo, ho benya ho hoholo) le ho tšoana ho hoholo ha botenya. Ts'ebetsong ena, polymer e qhibilihisitsoeng e ntšetsoa ka ho otloloha ka T-die e bataletseng, ea mofuta oa slot, e etsang webo e qhibilihisitsoeng e ts'oanang. Webo ena e huloa ka potlako holim'a roll e le 'ngoe kapa tse ngata tse lebelo le phahameng, tse pholileng ka hare. Ho qhibiliha hoa tiea kapele ha ho kopana le bokaholimo ba roll e batang. Lifilimi tse lahlehileng ka kakaretso li na le thepa e ntle ea optical, maikutlo a bonolo, le ho koaloa hantle ha mocheso. Taolo e nepahetseng holim'a lekhalo la lip ea die, mocheso oa roll ea chill, le lebelo la ho potoloha li lumella taolo e nepahetseng ea botenya ba filimi le boleng ba bokaholimo.

Liphephetso tse 6 tse ka Sehloohong tsa ho Ntša Filimi ea Polyolefin

Ho sa tsotellehe khōlo ea theknoloji ea extrusion, bahlahisi ba atisa ho kopana le letoto la mathata a ts'ebetso tlhahisong e sebetsang ea lifilimi tsa polyolefin, haholo-holo ha ba loanela tlhahiso e phahameng, bokhoni, litekanyo tse tšesaane, le ha ba sebelisa li-resin tse ncha tse sebetsang hantle. Litaba tsena ha li ame botsitso ba tlhahiso feela empa li boetse li ama ka kotloloho boleng ba sehlahisoa sa ho qetela le litšenyehelo. Liphephetso tsa bohlokoa li kenyelletsa:

1. Ho Qhaqha ha Melt (Sharkskin): Ena ke e 'ngoe ea liphoso tse tloaelehileng haholo ho extrusion ea filimi ea polyolefin. Ka macroscopic, e iponahatsa e le maqhubu a potolohang a nako le nako kapa bokaholimo bo sa tsitsang filiming, kapa maemong a boima, ho sotha ho hlahellang haholoanyane. Ho qhalana ha melt ho etsahala haholo-holo ha sekhahla sa ho qhaqha ha polymer e qhibilihang e tsoang ka har'a die se feta boleng ba bohlokoa, e leng se lebisang ho ho sisinyeha ha ho khomarela pakeng tsa lebota la die le ho qhibiliha ha bongata, kapa ha khatello ea katoloso ho tsoa ha die e feta matla a ho qhibiliha. Sekoli sena se beha thepa ea optical ea filimi kotsing e kholo (ho hlaka, ho benya), boreledi ba bokaholimo, 'me se ka boela sa senya thepa ea eona ea mechine le ea thibelo.

2. Ho Hlohlelletsa ho Hlohlelletsa ho Hlohlelletsa ho Hlohlelletsang: Sena se bolela ho bokellana butle-butle ha dihlahiswa tsa ho senyeha ha polymer, dikarolwana tse tlase tsa boima ba dimolek'hule, di-additi tse hasantsweng hampe (mohlala, di-pigment, di-antistatic agents, di-slip agents), kapa di-gel ho tswa ho resin mathōkong a molomo wa die kapa ka hara mokoti wa die. Di-deposit tsena di ka kgaohana nakong ya tlhahiso, tsa silafatsa bokahodimo ba filimi mme tsa baka diphoso tse kang di-gel, mela, kapa maqeba, ka hona tsa ama ponahalo le boleng ba sehlahiswa. Maemong a tebileng, ho bokellana ha die ho ka thibela ho tswa ha die, ho lebisang ho diphetoho tsa gauge, ho taboha ha filimi, mme qetellong ho qobelle ho kwalwa ha mela ya tlhahiso bakeng sa ho hlwekisa die, ho fellang ka tahlehelo e kgolo bokgoning ba tlhahiso le tshenyo ya thepa e tala.

3. Khatello e Phahameng ea Extrusion le Phapang: Tlas'a maemo a itseng, haholo-holo ha ho sebetsoa li-resin tse nang le viscosity e phahameng kapa ho sebelisoa likheo tse nyane tsa die, khatello e ka har'a sistimi ea extrusion (haholo-holo hloohong ea extruder le die) e ka ba holimo haholo. Khatello e phahameng ha e eketse feela tšebeliso ea matla empa hape e beha kotsi ho nako e telele ea lisebelisoa (mohlala, screw, barrel, die) le polokeho. Ho feta moo, liphetoho tse sa tsitsang khatellong ea extrusion li baka ka ho toba liphetoho tlhahisong ea ho qhibiliha, e leng se lebisang botenya ba filimi bo sa lekanang.

4. Phello e Lekanyelitsoeng: Ho thibela kapa ho fokotsa mathata a kang ho robeha ha qhibilihiso le ho bokellana ha die, bahlahisi hangata ba qobellwa ho fokotsa lebelo la sekurufu sa extruder, ka hona ba fokotsa tlhahiso ya mola wa tlhahiso. Sena se ama ka ho toba bokgoni ba tlhahiso le ditjeo tsa tlhahiso ka yuniti e le nngwe ya sehlahiswa, e leng se etsang hore ho be thata ho fihlela ditlhoko tsa mmaraka bakeng sa difilimi tse kgolo, tse theko e tlase.

5. Bothata ba Taolo ea Gauge: Ho se tsitse ha phallo ea ho qhibiliha, kabo ea mocheso o sa lekanang ho pholletsa le die, le ho bokellana ha die kaofela li ka tlatsetsa ho feto-fetohang ha botenya ba filimi, ka bobeli ka ho thibana le ka bolelele. Sena se ama ts'ebetso ea morao-rao ea ts'ebetso ea filimi le litšobotsi tsa tšebeliso ea ho qetela.

6. Phetoho e Thata ea Resin: Ha ho fetoloa pakeng tsa mefuta e fapaneng kapa maemo a fapaneng a li-resin tsa polyolefin, kapa ha ho fetoloa li-masterbatches tsa 'mala, lintho tse setseng tse tsoang nakong e fetileng hangata li thata ho li tlosa ka botlalo ho extruder le ho shoa. Sena se lebisa ho kopanngoa ha thepa ea khale le e ncha, ho hlahisa thepa ea phetoho, ho lelefatsa linako tsa phetoho, le ho eketsa sekhahla sa lithōle.

Liphephetso tsena tse tloaelehileng tsa ts'ebetso li sitisa boiteko ba bahlahisi ba lifilimi tsa polyolefin ho ntlafatsa boleng ba sehlahisoa le katleho ea tlhahiso, 'me hape li baka litšitiso ho amoheloeng ha thepa e ncha le mekhoa e tsoetseng pele ea ts'ebetso. Ka hona, ho batla litharollo tse sebetsang ho hlola liphephetso tsena ho bohlokoa bakeng sa nts'etsopele e tsitsitseng le e phetseng hantle ea indasteri eohle ea ho ntša lifilimi tsa polyolefin.

Litharollo tsa Ts'ebetso ea ho Ntša Filimi ea Polyolefin: Lithuso tsa ho Sebetsa ka Polymer (PPAs)

Lithuso tsa ho Sebetsa ka Polymer (PPAs) ke li-additives tse sebetsang tseo boleng ba tsona ba mantlha bo leng ho ntlafatseng boitšoaro ba rheological ba polymer e qhibilihang nakong ea ho ntša le ho fetola tšebelisano ea tsona le libaka tsa lisebelisoa, ka hona li hlōla mathata a mangata a ts'ebetso le ho ntlafatsa katleho ea tlhahiso le boleng ba sehlahisoa.

1. Li-PPA tse thehiloeng ho Fluoropolymer

Sebopeho le Litšobotsi tsa Lik'hemik'hale: Hona joale tsena ke sehlopha sa li-PPA tse sebelisoang haholo, tse hōlileng tsebong ea theknoloji, le tse bonahalang li sebetsa hantle. Hangata ke li-homopolymer kapa li-copolymer tse thehiloeng ho li-monomers tsa fluoroolefin tse kang vinylidene fluoride (VDF), hexafluoropropylene (HFP), le tetrafluoroethylene (TFE), 'me li-fluoroelastomer ke tsona tse emelang ka ho fetisisa. Liketane tsa limolek'hule tsa li-PPA tsena li ruile ka litlamo tsa CF tse nang le matla a phahameng, tse nang le polarity e tlase, tse fanang ka thepa e ikhethang ea physicochemical: matla a tlase haholo a holim'a metsi (a tšoanang le polytetrafluoroethylene/Teflon®), botsitso bo botle ba mocheso, le ho se sebetse hantle ha lik'hemik'hale. Ha e le hantle, li-PPA tsa fluoropolymer ka kakaretso li bontša ho se lumellane hantle le li-matrices tsa polyolefin tse seng tsa polar (joalo ka PE, PP). Ho se lumellane hona ke ntho ea bohlokoa bakeng sa ho falla ha tsona ka katleho ho ea libakeng tsa tšepe tsa die, moo li thehang lesela le matla la ho tlotsa.

Lihlahisoa tse Emelang: Lihlahisoa tse etellang pele 'marakeng oa lefats'e bakeng sa li-PPA tsa fluoropolymer li kenyelletsa letoto la Chemours' Viton™ FreeFlow™ le letoto la 3M's Dynamar™, tse nang le karolo e kholo ea' maraka. Ho phaella moo, mefuta e itseng ea fluoropolymer ho tsoa ho Arkema (letoto la Kynar®) le Solvay (Tecnoflon®) le eona e sebelisoa e le, kapa ke likarolo tsa bohlokoa, mefuteng ea PPA.

2. Lithuso tsa ho Sebetsa tse Thehiloeng ho Silicone (PPA)

Sebopeho le Litšobotsi tsa Lik'hemik'hale: Likarolo tse ka sehloohong tse sebetsang sehlopheng sena sa li-PPA ke li-polysiloxanes, tse tsejoang hangata e le li-silicone. Mokokotlo oa polysiloxane o na le liathomo tsa silicon le oksijene tse fapanyetsanang (-Si-O-), tse nang le lihlopha tsa lintho tse phelang (hangata methyl) tse khomaretsoeng liathomong tsa silicon. Sebopeho sena se ikhethang sa limolek'hule se fa lisebelisoa tsa silicone khatello e tlase haholo ea bokaholimo, botsitso bo botle ba mocheso, ho tenyetseha ho hotle, le thepa e sa khomareleng linthong tse ngata. Ho tšoana le li-PPA tsa fluoropolymer, li-PPA tse thehiloeng ho silicone li sebetsa ka ho fallela libakeng tsa tšepe tsa lisebelisoa tsa ts'ebetso ho theha lera la ho tlotsa.

Likarolo tsa Ts'ebeliso: Leha li-PPA tsa fluoropolymer li laola lekala la extrusion ea filimi ea polyolefin, li-PPA tse thehiloeng ho silicone li ka bonts'a melemo e ikhethang kapa tsa baka litlamorao tsa tšebelisano ha li sebelisoa maemong a itseng a ts'ebeliso kapa hammoho le litsamaiso tse itseng tsa resin. Mohlala, li ka nahanoa bakeng sa lits'ebetso tse hlokang li-coefficients tse tlase haholo tsa khohlano kapa moo litšobotsi tse itseng tsa bokaholimo li lakatsehang bakeng sa sehlahisoa sa ho qetela.

Na u tobane le Lithibelo tsa Fluoropolymer kapa Liphephetso tsa Phepelo ea PTFE?

Rarolla Liphephetso tsa ho Ntša Filimi ea Polyolefin ka Litharollo tsa PPA tse se nang PFAS-Li-additives tsa SILIKE tse se nang Fluorine Polymer

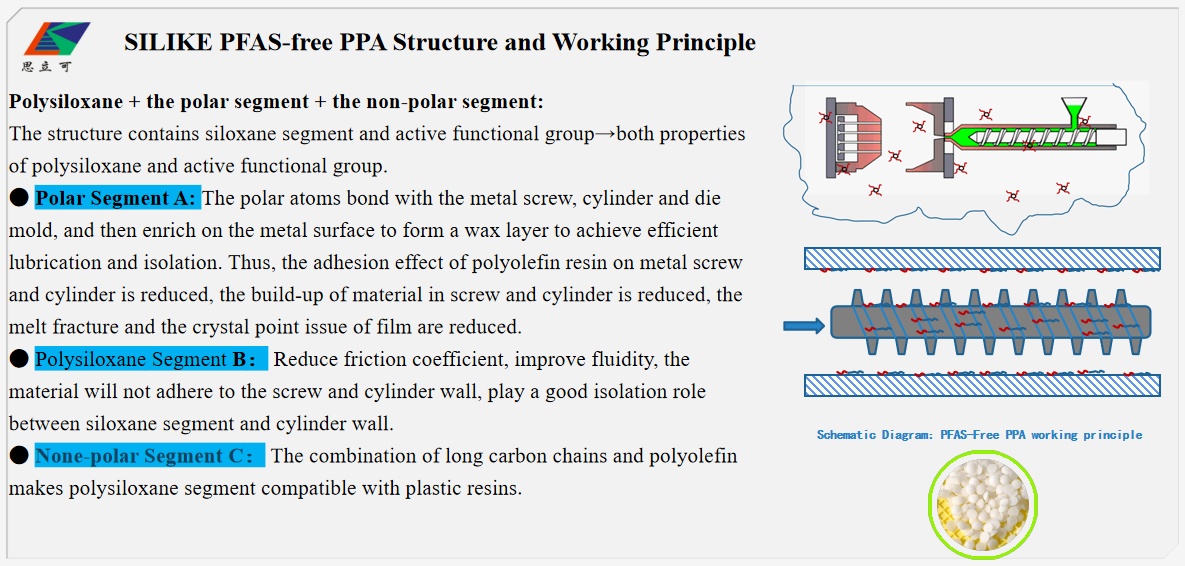

SILIKE e nka mokhoa oa ho nka bohato ka lihlahisoa tsa eona tsa letoto la SILIMER, e fana ka mekhoa e mechaLithuso tsa ho sebetsana le polymer tse se nang PFAS (PPAS)). Mohala ona o felletseng oa sehlahisoa o na le li-PPA tse hloekileng tsa 100% tse se nang PFAS,Lisebelisoa tsa polymer tsa PPA tse se nang fluorineleLi-masterbatches tsa PPA tse se nang PFAS le tse se nang fluorine.Kaho felisa tlhoko ea li-additives tsa fluorine, ts'ebetso ena e thusa haholo ho ntlafatsa ts'ebetso ea tlhahiso bakeng sa LLDPE, LDPE, HDPE, mLLDPE, PP, le lits'ebetso tse fapaneng tsa ho ntša filimi ea polyolefin. Li tsamaisana le melaoana ea morao-rao ea tikoloho ha ka nako e ts'oanang li eketsa katleho ea tlhahiso, li fokotsa nako ea ho se sebetse, le ho ntlafatsa boleng ba sehlahisoa ka kakaretso. Li-PPA tsa SILIKE tse se nang PFAS li tlisa melemo sehlahisoa sa ho qetela, ho kenyeletsoa le ho felisoa ha ho robeha ha qhibilihisoa (sharkskin), ho ntlafala ha boreleli, le boleng bo holimo ba bokaholimo.

Haeba o ntse o thatafalloa ke tšusumetso ea lithibelo tsa fluoropolymer kapa khaello ea PTFE lits'ebetsong tsa hau tsa ho ntša polymer, SILIKE e fana ka eona.mekhoa e meng e ka sebelisoang ho e-na le fluoropolymer PPAs/PTFE, Lisebelisoa tse se nang PFAS bakeng sa tlhahiso ea lifilimitse etselitsoeng litlhoko tsa hau, ntle le liphetoho tsa ts'ebetso tse hlokahalang.

Nako ea poso: Mots'eanong-15-2025