Na o tobane le Torque e Phahameng, Die Drool, kapa Phallo e Fosahetseng Metswakong ya Cable ya LSZH?

Lisebelisoa tsa cable tse se nang mosi o tlaase (LSZH) li ntse li le bohlokoa haholo bakeng sa polokeho ea cable ea sejoale-joale le botsitso. Leha ho le joalo, ho fihlella bokhoni bo botle ba ho sebetsa e ntse e le phephetso. Tšebeliso e matla ea li-filler tse thibelang malakabe—tse kang aluminium hydroxide (ATH) le magnesium hydroxide (MDH)—hangata li baka ho se phalle hantle, torque e phahameng, ho qeta bokaholimo bo matsutla, le ho bokellana ha shoa nakong ea ho ntša.

Hobaneng ha ho le thata ho sebetsana le LSZH Cable Compounds?

Litšobotsi tsa terata le thapo tse thibelang malakabe tse se nang mosi o tlase ke hore thepa eohle ha e na halogen, 'me mosi o monyenyane haholo o tla lokolloa nakong ea ho cha. E le ho finyella lintlha tsena tse peli tsa bohlokoa, ho ile ha eketsoa palo e kholo ea lintho tse thibelang malakabe ts'ebetsong ea tlhahiso, e leng se lebisang ka kotloloho letotong la mathata a ts'ebetso.

Tse latelang ke lintlha tse tloaelehileng tsa bohloko ba ts'ebetso ea metsoako ea cable e se nang halogen e ngata:

1. Ka lebaka la bongata ba di-filler tse thibelang malakabe tse kang aluminium hydroxide le magnesium hydroxide tse ekeditsweng, tse lebisang bokgoning bo bobe ba phallo, le tlhahiso ya mocheso wa khohlano nakong ya tshebetso di lebisa ho phahama ha mocheso, e leng se fellang ka ho senyeha ha aluminium hydroxide le magnesium hydroxide.

2. Bokgoni bo tlase ba ho ntša metsi, le lebelo le phahameng la ho ntša metsi, bokgoni ba ho ntša metsi ha bo fetohe.

3. Ka lebaka la ho se tsamaisane hantle ha di-polyolefin le di-retant tsa malakabe le di-filler tse ding, e leng se fellang ka ho hasana ho fokolang nakong ya ho sebetsa le ho fokotseha ha thepa ya mechini.

4. Ho hasana ho sa lekanang ha lintho tse thibelang malakabe tse sa pheleng tsamaisong ho lebisa sebakeng se bataletseng le ho hloka khanya nakong ea ho ntša.

5. Polarity ea sebopeho sa retardant ea malakabe le li-filler tse ling e etsa hore ho qhibiliha ho khomarele hlooho ea die, ho liehisa ho tlosoa ha thepa, kapa ho na ha limolek'hule tse tlase ka har'a motsoako, e leng se fellang ka ho bokellana ha thepa molomong oa die, ka hona ho ama boleng ba thapo.

Mokhoa oa ho rarolla thapo ea LSZH mathata ana a ts'ebetso le boleng ba bokaholimo?

Ho rarolla mathata ana,theknoloji ea silicone masterbatche fetohile tharollo e tšepahalang mefuteng ea metsoako ea LSZH, e ntlafatsang katleho ea ts'ebetso le ts'ebetso ea bokaholimo ntle le ho beha thepa ea mechini kapa ea motlakase kotsing.

Hobaneng ho le jwalosilicone masterbatch ke tharollo e sebetsangbakeng sa ho ntlafatsa ts'ebetso le ts'ebetso ea bokaholimo ba metsoako ea cable ea LSZH?

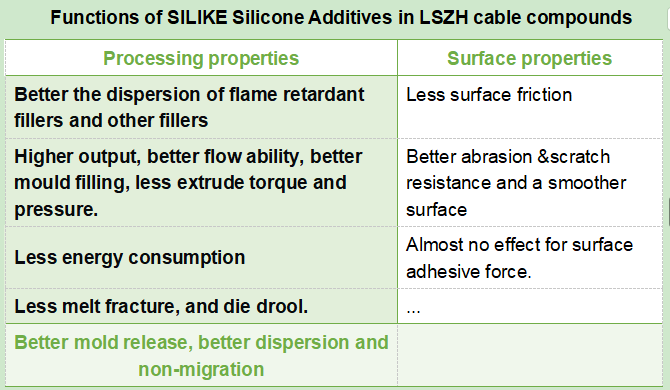

Silicone masterbatch ke mofuta oats'ebetso e sebetsang ea ho eketsaka li-thermoplastic tse fapaneng e le bajari le polysiloxane e le likarolo tse sebetsang. Ka lehlakoreng le leng, masterbatch e thehiloeng ho silicone e ka ntlafatsa bokhoni ba phallo ea sistimi ea thermoplastic nakong ea boemo bo qhibilihisitsoeng, ea ntlafatsa ho hasana ha li-filler, ea fokotsa tšebeliso ea matla ea extrusion le ente ea ho enta, le ho ntlafatsa katleho ea tlhahiso; Ka lehlakoreng le leng, thuso ena ea ts'ebetso e thehiloeng ho Silicone e ka boela ea ntlafatsa boreleli ba bokaholimo ba lihlahisoa tsa ho qetela tsa polasetiki, ea fokotsa coefficient ea khohlano ea bokaholimo le ho ntlafatsa ho tsofala le ho hanyetsa ho ngoapa. Ho phaella moo, e le thuso ea ts'ebetso bakeng sa indasteri ea thermoplastic, silicone masterbatch e ka fihlela phello e totobetseng ea phetoho ka bongata bo bonyenyane (< 5%), ntle le ho nahana haholo ka karabelo ea eona le thepa ea matrix.

Chengdu Silike Technology Co., Ltd. ke moetsi ea ka sehloohong oa Chaena ea ikhethang ka ho khethehali-additives tse thehiloeng ho siliconebakeng sa liindasteri tsa polasetiki le rabara. Ka lilemo tse fetang 20 tsa lipatlisiso tse inehetseng tse shebaneng le ho kopanngoa ha silicone le li-polymer, Silike e ipakile e le molekane ea nang le boqapi le ea tšepahalang bakeng sa litharollo tsa litlatsetso tse sebetsang hantle.

Ho thusa bahlahisi ho sebetsana le mathata a tlhahiso a amanang le likhoele tsa LSZH, Silike e ntlafalitse pokello e felletseng eali-additives tsa polasetiki tsa siliconee etselitsoeng ka ho khetheha ho ntlafatsa ts'ebetso ea metsoako ea cable. Lihlahisoa tse hlokomelehang, tse kang Silicone Masterbatch LYSI-401 le Silicone Masterbatch LYSI-502C, li fana ka litharollo tse sebetsang tse reretsoeng ho ntlafatsa ts'ebetso le boleng ba bokaholimo, ka hona li kenya letsoho ts'ebetsong e phahameng lits'ebetsong tsa terata le cable.

Melemo ea Tshebetso: Liphetho tse Tloaelehileng tsa Teko ea Silicone Masterbatch ho LSZH Cable Compounds

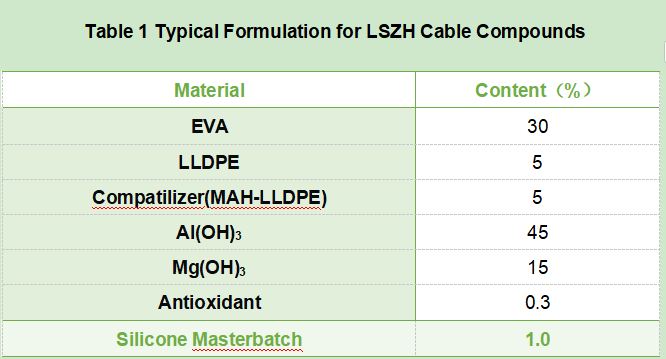

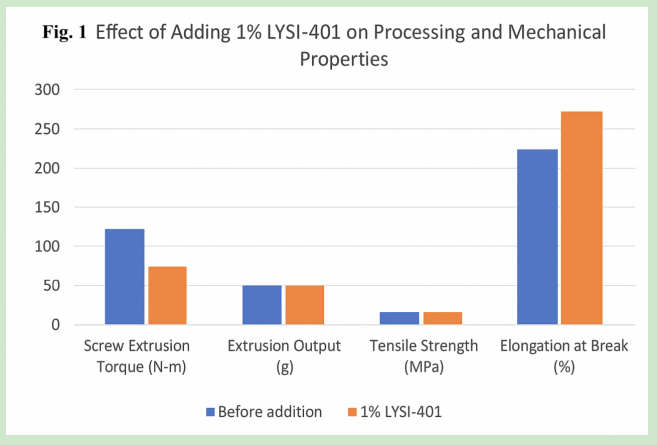

Ho eketsa SILIKESilicone Masterbatch (Siloxane Masterbatch) letoto la LYSIHo ea tsamaisong e phahameng ea ho tlatsa e thibelang malakabe ea thepa ea cable e se nang halogen e fokolang mosi ho ka ntlafatsa ho phalla ha ts'ebetso, ho fokotsa torque, le ho ntlafatsa katleho ea tlhahiso. Setšoantšo sa 1 se bontša papiso ea teko ea ts'ebetso ea cable kamora ho eketsa 1%Sehlopha se seholo sa silicone sa LYSI-401ka mokhoa o etsisitsoeng oa k'hamphani ea rona oa ho sebelisa halogen e fokolang e sa hlokeng mosi o mongata (Tafole ea 1). Ho ka bonoa hore ts'ebetso e amehang e ntlafalitsoe haholo.

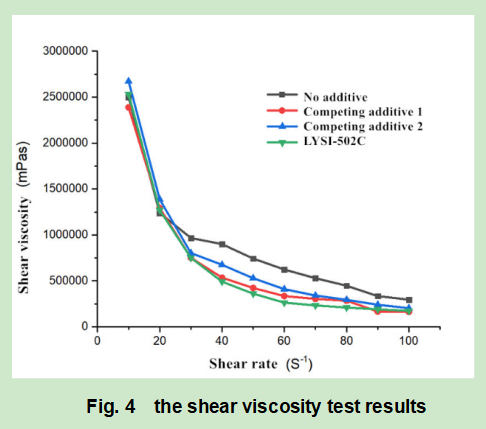

Setšoantšo sa 2, Setšoantšo sa 3, le Setšoantšo sa 4 li bontša teko ea torque rheometer ea siloxane High ContentSehlopha sa masterbatch sa silicone LYSI-502Ce ekelitsoe foromong e tloaelehileng e se nang halogen e nang le mosi o tlase le papiso le torque, khatello, le viscosity ea ho beola ea lihlahisoa tsa tlholisano tsa kantle ho naha. Ho ka bonoa hore LYSI-502C e na le ts'ebetso e ntle ea ho tlotsa.

Setšoantšo sa 5 se fana ka ketsiso ea bohlokoa ea pokello ea thepa ka har'a die ea extrusion ea cable kamora ho eketsoa ha silicone masterbatch. Liphetho li senola hore ho kenyelletsoa ha silicone masterbatch e tloaelehileng ho fokotsa haholo ho bokellana ha die. Ho feta moo, SILIKE'smasterbatch e phahameng ea limolek'hule ea siliconee bonts'a phello e hlahelletseng le ho feta ho fokotseng ho bokellana ha die, e leng se bontšang monyetla oa eona oa ho ntlafatsa katleho ea ts'ebetso.

Kakaretso:Siloxane e teng ka mokhoa o tloaelehilengli-masterbatches tsa siliconeha e na polar, e leng se ka bakang diphephetso ka lebaka la diparamitha tse fapaneng tsa ho qhibiliha ha di-polymer tse ngata tsa ketane ya khabone. Ha ho eketsoa ho le hoholo, ho ka lebisa mathateng a kang ho thella ha dikurufu, ho tlotsa ho feteletseng, ho kgaola bokahodimo ba sehlahiswa, tshebetso e sitisang ya ho tlamahana, le ho hasana ho sa lekanang ka hara substrate.

Ho rarolla liphephetso tsena, SILIKE e qapile letoto lali-additives tsa silicone tse boima ba limolek'hule tse phahameng haholotse fetoloang ka lihlopha tse khethehileng tsa ts'ebetso. Tsenalisebelisoa tse ling tsa ho sebetsana le polymer tse thehiloeng ho siliconeli etselitsoe ho fihlela litlhoko tse itseng tsa ts'ebeliso ho pholletsa le litsamaiso tse fapaneng tsa thermoplastic. Ka ho sebetsa e le liankora ka har'a substrate, li ntlafatsa ho lumellana, li ntlafatsa ho hasana, 'me li matlafatsa ho khomarela. Sena se fella ka ts'ebetso e ntlafetseng haholo ea substrate ka kakaretso. Litsamaisong tse se nang mosi o tlase, tse se nang halogen, li-additives tsena tse ncha li thibela ho thella ha li-screw ka katleho 'me li fokotsa haholo ho bokellana ha thepa ea die.

Na o batlasesebelisoa sa ho lokisa polymerho ntlafatsa ts'ebetso ea hau ea tlhahiso ea lithapo tsa LSZH?

Hlahloba kamoo ditharollo tsa masterbatch tse thehilweng ho silicone tsa SILIKE, ho kenyeletswa le sehlomathiso sa silicone sa LYSI-401 le siloxane masterbatch LYSI-502C, di ka o thusang ho ntlafatsa tlhahiso, ho fokotsa tlhokomelo ya die, le ho fihlella boleng bo hodimo ba thapo. Re o mema hore o ikopanye le rona bakeng sa tlhahisoleseding e batsi le ho kopa sampole.

Webosaete: www.siliketech.com

Email: amy.wang@silike.cn

Nako ea poso: Mphalane-10-2025