Polycarbonate (PC) ke e 'ngoe ea li-thermoplastic tsa boenjiniere tse feto-fetohang ka ho fetisisa tse sebelisoang lilenseng tsa likoloi, lisebelisoa tsa elektroniki tsa bareki, liaparo tsa mahlo le lisebelisoa tsa tšireletso. Matla a eona a tšusumetso e phahameng, ho hlaka ha mahlo, le botsitso ba litekanyo li etsa hore e be e loketseng lits'ebetso tse thata. Leha ho le joalo, bothata bo tsebahalang ba PC ke ho thatafala ha eona holim'a bokaholimo, e leng se lebisang ho ho hlohlona le ho se tsofale hantle - haholo-holo tlas'a maemo a ho kopana khafetsa kapa a ho hlaba.

Kahoo, bahlahisi ba ka ntlafatsa ho tšoarella ha bokaholimo ba PC joang ntle le ho beha pepeneneng ea eona kapa thepa ea mechini kotsing? A re hlahlobeng mefuta e fapaneng ea litharollo tse sebetsang le mekhoa e netefalitsoeng ke indasteri ho hlola liphephetso tsena.

Tharollo: Kopanya ntlafatso ea ts'ebetso le liphetoho tsa thepa ea bokaholimo le mahlale a tsoetseng pele a tšireletso.

1. Lisebelisoa tse Thehiloeng ho Silicone: Ho tlotsa ha kahare

Ho kenyelletsa li-additives tsa silicone tse sebetsang hantle, tse kang polydimethylsiloxane (PDMS) kapa li-masterbatches tse thehiloeng ho siloxane tse kang Dow MB50-001, Wacker GENIOPLAST, le SILIKE Silicone Masterbatch LYSI-413, ka har'a li-formulations tsa polycarbonate (PC) ho ka ntlafatsa ts'ebetso ea thepa haholo. Ka ho sebelisa li-additives tsena boemong ba ho jara ba 1-3%, u ka fokotsa coefficient ea khohlano ka katleho, e leng se ntlafatsang ho hanyetsa ho ngoapa le ho tšoarella ha ho tsofala.

Melemo ea Bohlokoa: Lisebelisoa tsena tsa silicone, e le lisebelisoa tsa ho sebetsana le PC le li-modifiers, ha li boloke feela ho hlaka ha mahlo ha PC empa hape li eketsa ho tlotsa ha bokaholimo. Sena se fella ka phokotso e makatsang ea tšenyo ea bokaholimo nakong ea ho kopana le ho khohlela, qetellong e lebisang ho ntlafatseng nako e telele ea sehlahisoa.

Keletso e Sebetsang: Ho netefatsa ts'ebetso e ntle ka ho fetisisa, ho bohlokoa ho fihlella ho hasana ho nepahetseng ka ho ntša li-screw tse peli, e leng se thusang ho thibela karohano ea mekhahlelo le ho eketsa melemo ea li-additives.

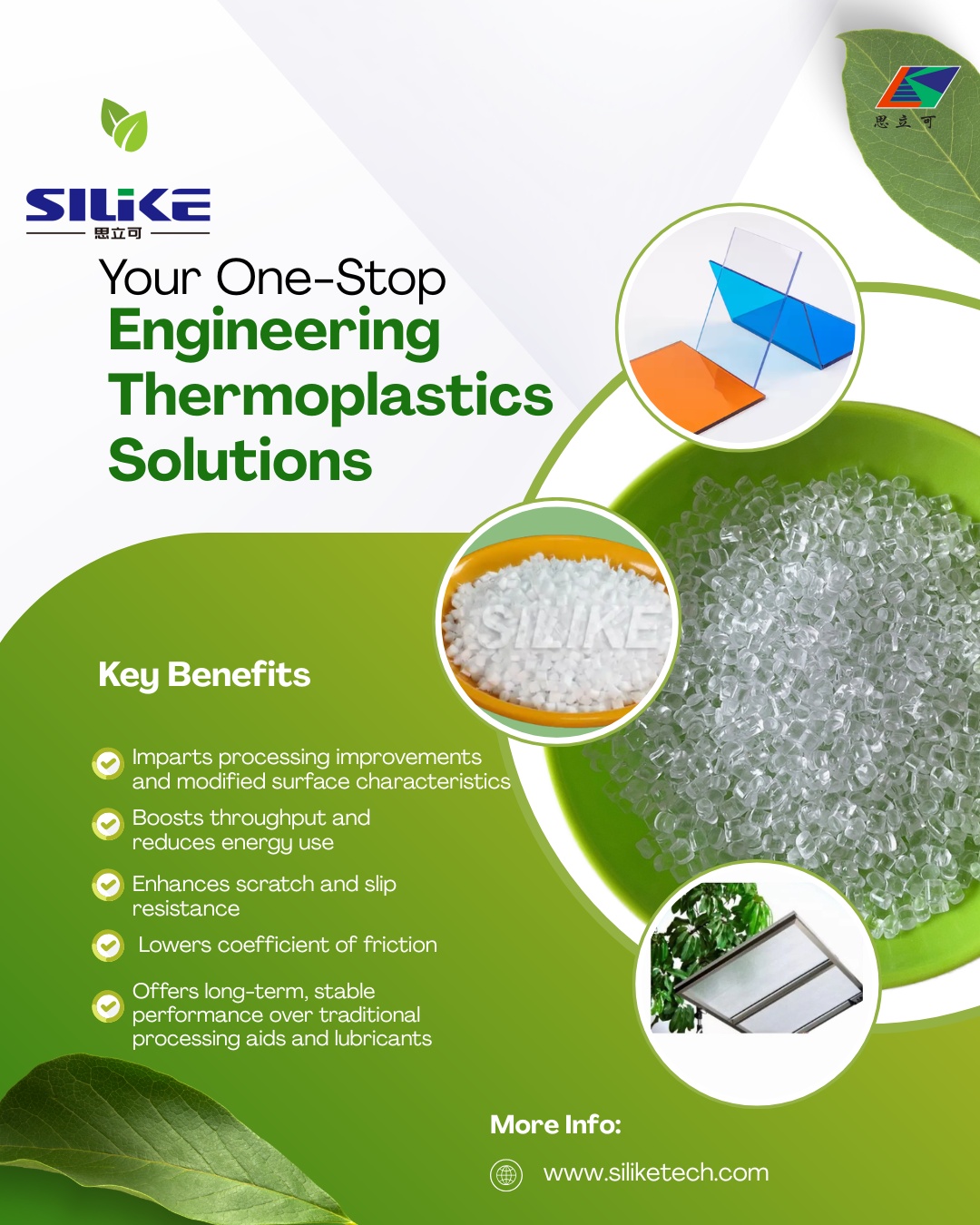

Chengdu SILIKE Technology Co., Ltd ke mofani ea ka sehloohong oa thepa oa China oali-additives tsa silicone bakeng sa polasetiki e fetotsoengKhamphani e fana ka ditharollo tse ntjha tse reretsweng ho ntlafatsa tshebetso le tshebetso ya thepa e fapaneng ya polasetiki. E nngwe ya dihlahiswa tsa bona tse ikgethang keSILIKE Silicone Masterbatch LYSI-413,Sebopeho se sebetsang hantle haholo sa pellet se nang le polymer ea siloxane e boima ba limolek'hule ea 25% e hasantsoeng ka polycarbonate (PC). Sesebelisoa sena se thehiloeng ho silicone se sebetsa haholo bakeng sa litsamaiso tsa resin tse lumellanang le PC. Se ntlafatsa thepa ea ts'ebetso le boleng ba bokaholimo ka ho ntlafatsa phallo ea resin, ho nolofatsa ho tlatsa le ho lokolla hlobo, ho fokotsa torque ea extruder, ho theola coefficient ea khohlano, le ho fana ka khanyetso e phahameng ea mar le abrasion. Ho feta moo, masterbatch ena e thehiloeng ho siloxane e sebetsa e le sesebelisoa se thibelang ho hlaba, e leng se etsang hore e be tharollo e ntle ea ho eketsa khanyetso ea ho hlaba ea lihlahisoa tsa PC le ho ntlafatsa ts'ebetso ea tsona ka kakaretso le ho tšoarella.

2. Liaparo tse thata tse folisoang ke UV tse nang le Nanotechnology

Kenya dikobo tse thata tse thehilweng ho siloxane kapa tse kopantsweng tsa tlhaho tse sa tswakwang (mohlala, Momentive SilFORT AS4700 kapa PPG's DuraShield). Dikobo tsena di fihlela boima ba pentšele ho fihlela ho 7H-9H, e leng se ntlafatsang haholo ho hanyetsa ho ngoatheha.

Kenya dikobo tse folisoang ke UV ka nanoparticles (mohlala, silica kapa zirconia) ho eketsa ho hanyetsa ho kgohlopa.

Molemo: E fana ka tšireletso khahlanong le mengoapo, lik'hemik'hale le ho senyeha ha mahlaseli a kotsi a UV, e loketseng lits'ebetso tsa mahlo le tsa likoloi.

Tšebeliso: Sebelisa sekwahelo sa ho qoelisa, sekwahelo sa ho fafatsa, kapa sekwahelo sa ho phalla bakeng sa botenya bo lekanang (5-10 µm).

3. Matlafatso ea Nanocomposite

Kenya di-nanofiller tse kang nanosilica, alumina, kapa graphene oxide (0.5-2% ka boima) ho PC matrix. Tsena di eketsa thatafalo ya bokahodimo mme di ntlafatsa ho hanyetsa ho tsofala ntle le ho ama pepeneneng haholo haeba boholo ba dikarolwana bo le <40 nm.

Mohlala: Lithuto li bontša hore nanosilica ea 1% ho PC e ka ntlafatsa khanyetso ea ho qhaqhoa ha Taber ka 20-30%.

Keletso: Sebelisa lintho tse tsamaisanang le tsona (mohlala, li-sylane coupling agents) ho netefatsa hore li hasane ka ho lekana le ho qoba ho kopana.

4. Metswako ea PC bakeng sa Tshebetso e Leka-lekaneng

Kopanya PC le PMMA (10-20%) ho ntlafatsa thatafalo ya bokaholimo kapa ka PBT bakeng sa ho ntlafala ha ho tiea le ho hanyetsa ho tsofala. Tsena di kopanya ho leka-lekanya ho hanyetsa ho ngoapa le matla a tlhaho a PC a ho tshwarwa.

Mohlala: Motsoako oa PC/PMMA o nang le 15% PMMA o ka eketsa ho thatafala ha bokaholimo ha o ntse o boloka ho hlaka bakeng sa lits'ebetso tsa ponts'o.

Tlhokomeliso: Ntlafatsa dikarolelano tsa motswako ho qoba ho beha botsitso ba mocheso kapa ho tiea ha PC kotsing.

5. Mekhoa e Tsoetseng Pele ea Phetoho ea Bokaholimo

Kalafo ea Plasma: Sebelisa plasma-enhanced chemical vapor deposition (PECVD) ho kenya masela a masesaane, a thata joalo ka silicon oxynitride (SiOxNy) holim'a libaka tsa PC. Sena se ntlafatsa ho hanyetsa ho ngoapa le litšobotsi tsa ho tsofala.

Ho Sebetsa ka Laser: Etsa dibopeho tse nyane kapa tse nyane hodima bokahodimo ba PC ho fokotsa sebaka sa ho kopana le ho hasanya mengwapo, ho ntlafatsa ho tshwarella ha botle.

Molemo: Ho lokisa mongolo ho ka fokotsa ho ngoatheha ho bonahalang ka ho fihla ho 40% lits'ebetsong tse nang le ho kopana ho hoholo.

6. Metswako e Eketsehileng bakeng sa Kopano

Kopanya di-additives tsa silicone le di-additives tse ding tse sebetsang jwalo ka di-micropowders tsa PTFE (polytetrafluoroethylene) (0.5-1%) bakeng sa ditlamorao tsa ho kopanya. PTFE e eketsa ho tlotsa, ha silicone e ntlafatsa ho hanyetsa ho tsofala.

Mohlala: Motswako wa 2% silicone masterbatch le 0.5% PTFE o ka fokotsa sekgahla sa ho tsofala ka 25% ditshebedisong tse thellang.

7. Maemo a Ts'ebetso a Ntlafalitsoeng:

Sebelisa motsoako o nang le sekere se phahameng ho hasanya li-additives le li-filler ka mokhoa o ts'oanang. Boloka mocheso oa ts'ebetso ea PC (260-310°C) ho qoba ho senyeha.

Sebelisa mekhoa ea ho bōpa ka nepo (mohlala, ho bōpa ka ente ka hlobo e bentšitsoeng) ho fokotsa liphoso tsa bokaholimo tse ka bakang ho ngoathoa.

Likarolo tse bōpiloeng ka Anneal mochesong oa 120-130°C ho imolla khatello ea ka hare, ho ntlafatsa ts'ebetso ea ho robeha ha nako e telele.

Tlhokomelo ea Boiqapelo: Ho Ipholisa le Liaparo tsa DLC lia Hola

Mahlale a macha a kang a ho ipholisa (a thehiloeng k'hemistring ea polyurethane kapa siloxane) le a ho ipholisa joaloka daemane (DLC) a fana ka litharollo tse tla sebetsa nakong e tlang bakeng sa lits'ebetso tsa PC tse tšoarellang haholo, tse nang le matla a ho ama. Leha li ntse li le theko e tlase bakeng sa lihlahisoa tse rekisoang ka bongata, mahlale ana a bontša tšepo ho lisebelisoa tsa elektroniki tsa mabothobotho, likoloi le lifofane.

Mokhoa o Khothaletsoang bakeng sa Tshebetso e Ntle ho Thermoplastics ea Boenjiniere

Bakeng sa bahlahisi ba batlang tharollo e sebetsang, e ka atolosoang ho ntlafatsa ho tšoarella ha bokaholimo ba PC, re khothaletsa:

1)Sesebelisoa sa Silicone sa 2% UHMW bakeng sa ho tlotsa kahare

2) Sekoahelo sa UV se thehiloeng ho Siloxane + 1% Nano Silica bakeng sa ho thatafala ha bokaholimo

3) Micro-Texturing ka Laser Molding ho pata mengoapo

Mokhoa ona o nang le mahlakore a mararo o fana ka tekano ea ho boloka litšenyehelo, ho lumellana ha ts'ebetso, le ts'ebetso, e leng se etsang hore e be e loketseng lihlahisoa tse pepesehetseng ho tsofala letsatsi le letsatsi le tse hlokang botle bo tšoarellang nako e telele.

Indasteri e Pakiloe

Ho ea ka tlaleho ea 2024 ea MarketsandMarkets, 'maraka oa lefats'e oa li-hard coat o lebelletsoe ho feta $1.3 bilione ka 2027, o susumetsoa ke tlhoko e ntseng e hola ea polasetiki e sa ngoatheng lipontšong tsa likoloi, lisebelisoa tsa mohala le lilense tsa mahlo. Li-formulator tsa thepa le li-compound tse kopanyang li-additives tse sebetsang ka bongata le li-nano-filler li boemong bo botle ba ho etella pele moloko o latelang oa lihlahisoa tse tšoarellang tse thehiloeng ho PC.

Na u se u loketse ho ntlafatsa polasetiki ea hau ea boenjiniere joalo ka PC ka ho qojoa le ho hanyetsa ho tsofala ho betere?

Hlahloba SILIKElisebelisoa tsa polasetikiditharollo tse ntlafatsang ts'ebetso le thepa ya bokaholimo ho fihlela ditlhoko tsa hao tsa ho tshwarella.

For further information, please visit our website at www.siliketech.com, or contact us at Tel: +86-28-83625089 or via email at amy.wang@silike.cn. we provide ditharollo tse sebetsang hantle tsa ho sebetsana le polasetiki.

Nako ea poso: Phupu-02-2025